OLIVE NET FANOURAKIS, produces high quality Nets for Olive Collection, as well multi-application nets. In the Company’s philosophy, priority is the Quality of Products and Services. To this end, the contribution of the ISO 9001: 2015 Quality Management System issued by the International Certification Organization of TÜV Austria has played an essential role.

The continuous improvement of the quality management system and ensuring an even further effective implementation, achieving annual quality objectives, is an explicit commitment of OLIVE NET FANOURAKIS.

QUALITY CONTROL

OLIVE NET FANOURAKIS conducts quality control with strict specifications at all stages of the production process, from the receipt of the raw materials to the final product.

For this purpose, the company has invested in specialized equipment and instruments of high-tech measurement, while at the same time has accumulated considerable know-how in the organization and efficient operation, of a high-quality Quality Control Department.

KEY QUALITY CONTROL TOOLS

Main quality control instruments in the OLIVE NET FANOURAKIS Laboratory can be described as follows:

- Thickness meter: Gradually measuring thickness of the yarn so that an accurate cross section can be achieved.

- Climate chamber: Allows simulation of fabric behavior over time through the exposure of test samples to a human-induced test environment. Information on the effect of UV radiation on the final product results is also achieved. Conclusions that can be observed are: bleaching, discoloration, loss of light, turbidity, loss of strength and oxidation.

- Digital light meter (Luxo meter): adjusting the lighting to the desired levels (Shadowing power).

- Microscopes: with advanced features for study – fiber recognition.

- Laboratory scales: for weighing in grams accuracy.

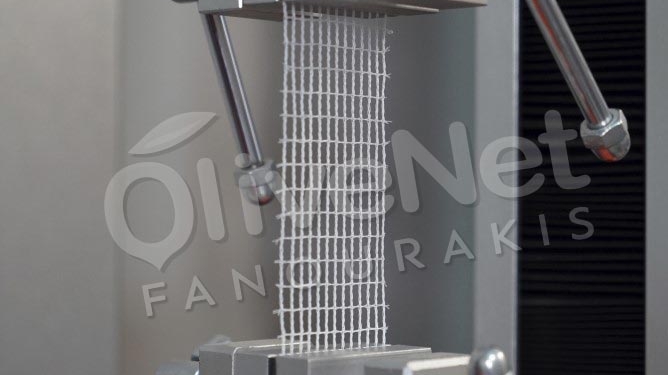

- Tensile and Material Strength Control: Allows various types of testing to be performed on the mechanical properties of fabrics and yarns.

- Perforation and resistance device: to measure fabric strength under certain forces.

- Air permeability test equipment: The device measures the amount of air perpendicular to the test sample. Through the test, the physical characteristics of the materials are checked to meet the practical application requirements.

- MFI Melt Flow Regulator: controls the melt flow of thermoplastic raw materials (grains).

- Appropriate quality control software: to control, record all measurements of lab devices.

LABORATORY CONDITIONS

OLIVE NET FANOURAKIS’s quality control laboratory is subject to controlled environmental conditions so that reliability of results can be ensured, thereby comparability and repeatability of the processes can be achieved.